Trench Heaters – PKOC for heating

![]()

Trench Heaters – PKOC for heating

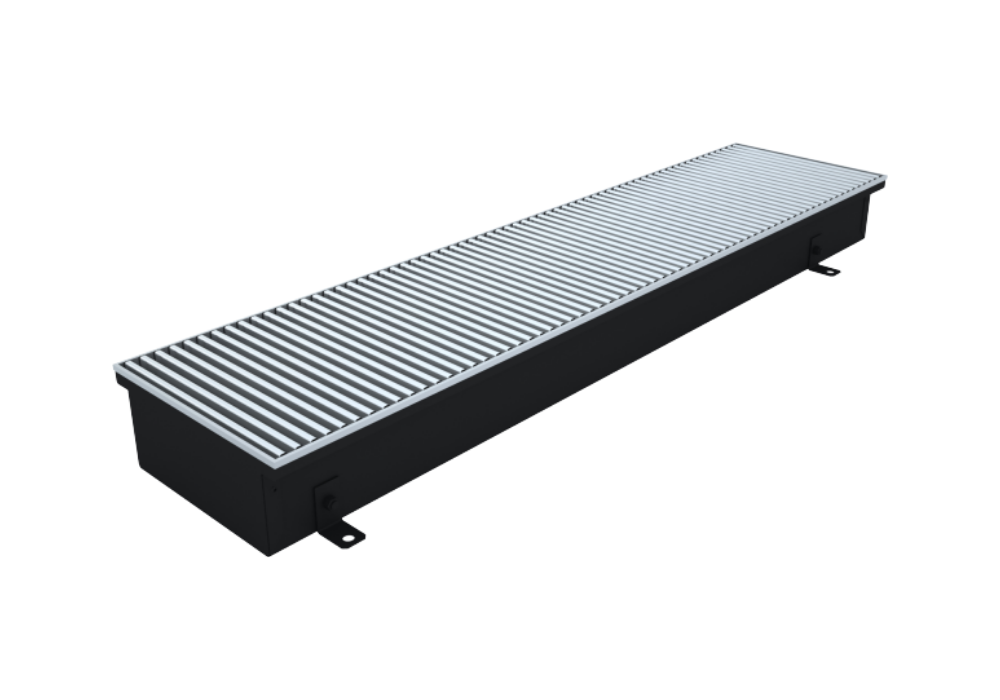

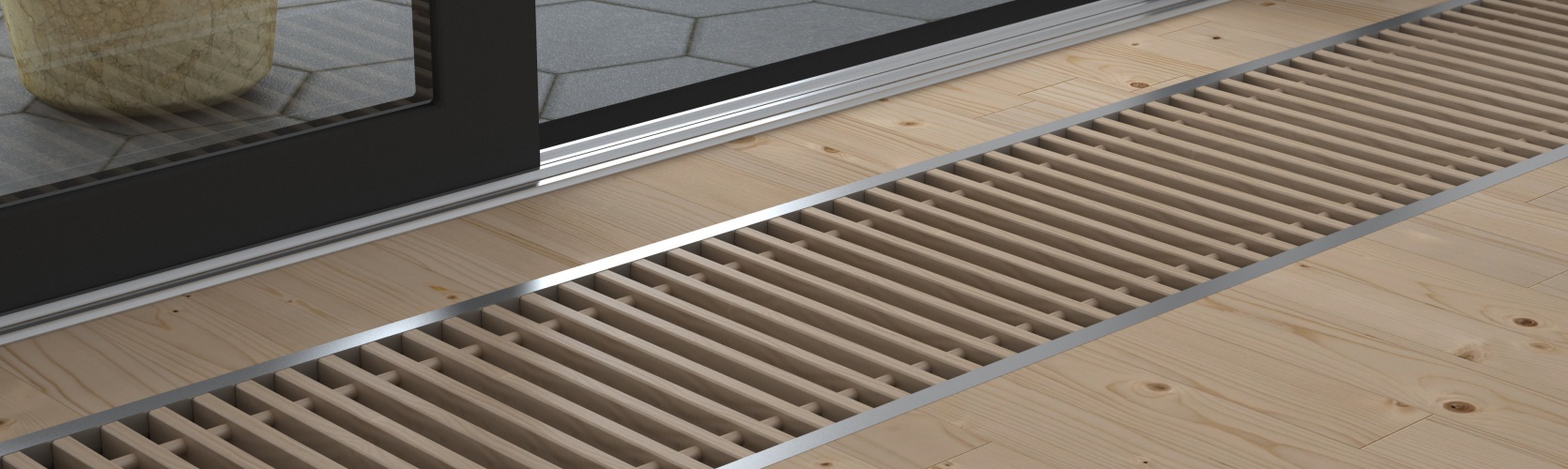

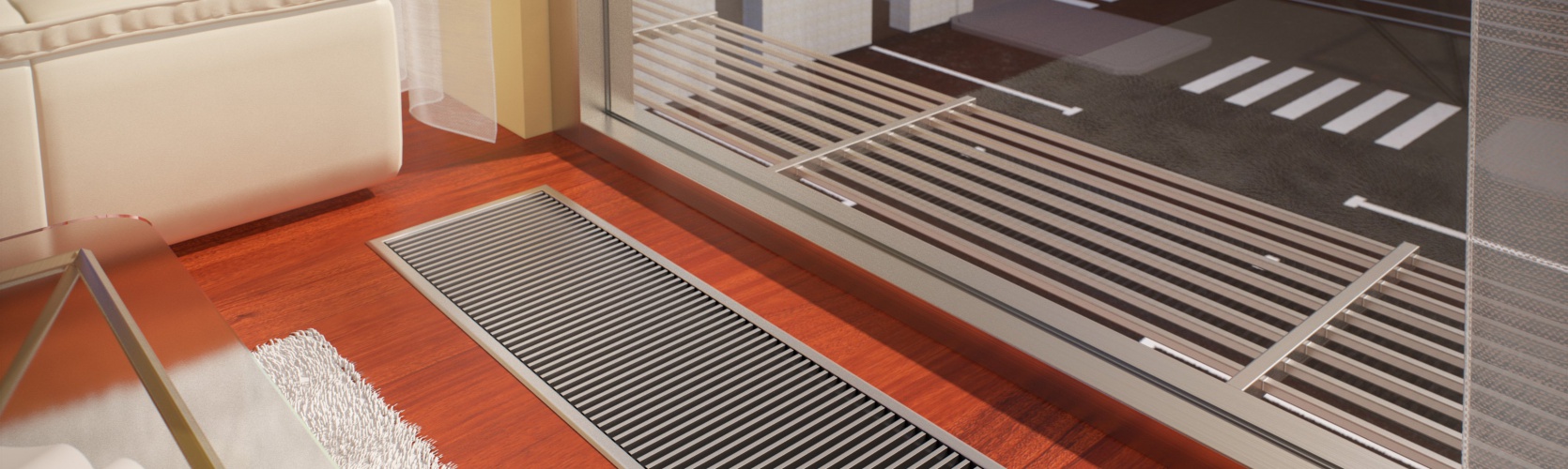

There are places with higher heat losses. Choose floor convectors Licon with forced convection and optimized convection in places where the efficiency must be increased while preserving the state of the art design.

• wide use possibilities

• convector increased heat efficiency

• very quiet operation

• energy saving fans with electric engine and minimal input

- Description

- Technical

- Heat outputs

- Accessories & standard supply

- Overview of types

- Assembly

- Downloads

- Inquiry form

Technical

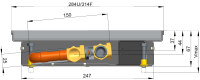

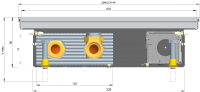

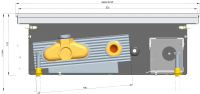

ctors with forced convection Licon PKOC 7/28

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 284U/314F |

| floor case width (mm) | 247 |

| grid width (mm) | 272 |

| max. adjustable height (H max. mm) | 67–94 |

| case depth (mm) | 67 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 25 |

| exchanger width (mm) | 150 |

| exchanger effective length (mm) | L – 370 |

| fans impeller diameter (mm) | 30 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

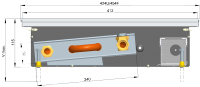

Floor convectors with forced convection Licon PKOC 8/16

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 164U/194F |

| floor case width (mm) | 127 |

| grid width (mm) | 152 |

| max. adjustable height (H max. mm) | 85–110 |

| case depth (mm) | 85 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 50 |

| exchanger width (mm) | 50 |

| exchanger effective length (mm) | L – 400 |

| fans impeller diameter (mm) | 30 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

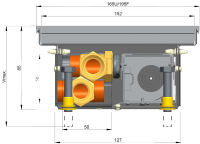

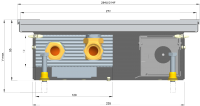

Floor convectors with forced convection Licon PKOC 8/28

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 284U/314F |

| floor case width (mm) | 235 |

| grid width (mm) | 272 |

| max. adjustable height (H max. mm) | 80–107 |

| case depth (mm) | 80 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 50 |

| exchanger width (mm) | 120 |

| exchanger effective length (mm) | L – 350 |

| fans impeller diameter (mm) | 30 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

Floor convectors with forced convection Licon PKOC 9/28

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 284U/314F |

| floor case width (mm) | 235 |

| grid width (mm) | 272 |

| max. adjustable height (H max. mm) | 95 -122 |

| case depth (mm) | 95 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 50 |

| exchanger width (mm) | 120 |

| exchanger effective length (mm) | L – 350 |

| fans impeller diameter (mm) | 40 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

Floor convectors with forced convection Licon PKOC 11/20

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 204U/234F |

| floor case width (mm) | 173 |

| grid width (mm) | 192 |

| max. adjustable height (H max. mm) | 108 -132 |

| case depth (mm) | 108 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 75 |

| exchanger width (mm) | 75 |

| exchanger effective length (mm) | L – 400 |

| fans impeller diameter (mm) | 40 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

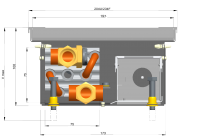

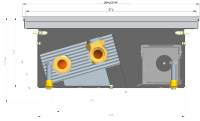

Floor convectors with forced convection Licon PKOC 11/28 (the best selling type)

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 284U/314F |

| floor case width (mm) | 235 |

| grid width (mm) | 272 |

| max. adjustable height (H max. mm) | 115 -142 |

| case depth (mm) | 115 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 50 |

| exchanger width (mm) | 120 |

| exchanger effective length (mm) | L – 350 |

| fans impeller diameter (mm) | 40 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

Floor convectors with forced convection Licon PKOC 11/34

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 344U/374F |

| floor case width (mm) | 295 |

| grid width (mm) | 332 |

| max. adjustable height (H max. mm) | 115 -142 |

| case depth (mm) | 115 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 50 |

| exchanger width (mm) | 180 |

| exchanger effective length (mm) | L – 350 |

| fans impeller diameter (mm) | 40 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

Floor convectors with forced convection Licon PKOC 11/42

| Version Economic | black coated zinc galvanised steel case, heat exchanger without any surface finish |

| Version Exclusive * custom-made design | black coated zinc galvanised steel case, black coated exchanger |

| Version Inox * custom-made design | stainless steel unpainted case AISI 304, unpainted exchanger (for dry environment only) |

| width including the U/F type frame (mm) | 424U/454F |

| floor case width (mm) | 375 |

| grid width (mm) | 412 |

| max. adjustable height (H max. mm) | 115 -142 |

| case depth (mm) | 115 |

| length (L mm) | 800 up to 2 800 (at 400 mm steps) |

| exchanger height (mm) | 50 |

| exchanger width (mm) | 240 |

| exchanger effective length (mm) | L – 350 |

| fans impeller diameter (mm) | 40 |

| connection to the heating system | 2× G 1/2″ inner |

| case material | galv. steel, stainless steel AISI 304 |

Heat outputs

Accessories & standard supply

Standard delivery contains

|

Optional accessories

|

Profiles of aluminium frames |

|

Standard design – U frameStandard PK design contains silver U profile. Profile colour is equal with grid colour, for other colours. |

Selectable version – F frameWhen the selectable frame F is ordered, it is attached separately to convector (not installed on convector). Frame colours are identical with aluminium grid colours. |

Overview of types

Assembly

Convector installation – construction part Licon PKOC

Convector installation – construction recommendations Several general principles must be fulfilled to ensure proper functioning of the convector.

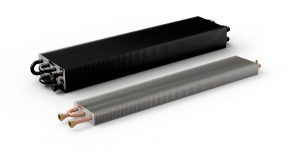

• A properly installed element has the exchanger located further away from the window.

• It is recommended to use the standard stainless-steel hoses with stainless-steel jacketing which always form a part of the delivery (unless recommended otherwise) for interconnecting the exchanger and the distributing pipeline. In practice they provide a better access under the heat exchanger without having to dismantle the heating system, e.g. during cleaning.

• We recommend connecting the heating system with the use of stop valves and a thermostatic valve.

• Always connect the supply of the heat-carrying medium to the heat exchanger’s pipe that is further away from the fan. In case of the 34 cm width the OR-J3 heat exchanger is used; the heatcarrying medium enters through one pipe and leaves through another one.

• The PKWOC exchanger is a four pipe unit; one circuit feeds the heating circuit and the other one the cooling circuit.

• Properly installed convector is laid horizontally with the convector’s case edges intact and not bent to ensure correct function of the walkable grid and the bleeding of the exchanger possible.

• Correctly installed convector’s decorative frame is at the floor level with a margin of +2 mm.

• We recommend to keep the cover plate on the convector for the entire duration of the building work to prevent any dirt falling inside the convector. The standard plate is not walkable, but a plate with increased load bearing capacity can be ordered.

• The fans set is held down to the convector’s case using magnets. In case of the stainless steel version the set of fans will be mounted using dry zips. This system allows you to remove the fans from the convector during the installation to avoid their damage or soiling, etc. They can be easily taken out for cleaning also during standard operation.

•The floor convector must be firmly set in the floor. The setting screws are only used for horizontal levelling of the convector case.

• Before concreting the convector must be fixed to the floor using anchoring screws that will prevent vertical shifting of the convector during subsequent pouring of concrete. When the concrete is poured the convector can be loaded vertically. During concreting the convector must be cross-braced to prevent deformation of the case. When pouring other material (e. g. anhydride) seal thoroughly all openings of the convector to prevent it from flooding.

• The convector’s PKBOC setting screw consists of a flag used as a ground anchor. This type does not contain anchors.

• We recommend the fixing and sound proof insulation to be done in such a way that will allow a thin concrete to be poured to the convector’s bottom and its sides. Optimal noise reduction is achieved by direct embedding of the convector in concrete.

• Installing the fan convector in free space can result in increased noise, therefore we recommend to order a case with noise absorbing foil.

• Installation into double layer floors is described later.

• Cooled convectors (PKIOC, PKWOC) have built-in as standard a water (condensate) drain. During the installation do not forget to interconnect the case at the bottom of the convector with a pipeline with guaranteed gradient for wastewater or condensate removal. We recommend to equip the drain with an odour trap.

• Convectors PKBOC are intended for use in swimming pool areas. The separation barrier is used to capture water from the pool, but cannot serve as the standard pool water overflow. This part is always placed closer to the pool. The heating part with the exchanger and fans must be always further away from the pool. The convector is provided with drainage holes in each corner, 2×. Installation, operation and maintenance of this equipment require special conditions. Please read them thoroughly on our website or in the manual.

Caution: Floor convector PKBOC with forced convection must be positioned so as to prevent even short term flooding of the section fitted with the motor and the fans.

Possibilities of convector incorporation by floor types

- Installation by embedding in concrete

- Installation in low double floor

- Installation in raised double floor

Dimensions of the mounting holes

Weights and water volumes

| Type | 7/28 | 8/16 | 8/28 | 9/28 | 11/20 | 11/28 | 11/34 | 11/42 |

| steel kg/linear meter | 7,06 | 5,38 | 7,3 | 8,5 | 6,53 | 9 | 11,2 | 12 |

| stainless steel kg/1 linear meter | 7,05 | 5,3 | 7,1 | 8,3 | 6,4 | 9 | 11 | 12 |

| l/1 linear meter | 0,4 | 0,22 | 0,4 | 0,4 | 0,5 | 0,4 | 0,6 | 0,8 |

Downloads

Assembly instruction 24-PKOC, PKIOC, PKWOC

Assembly instruction Regulace_24V

Assembly instruction PM

Ordering codes PKOC

Connection diagram

Regulation and acoustics

12-V convector regulation – termination of sale

Starting from March 2020 we terminate production and sale of 12-V convector regulation. This type of regulation can by fully replaced by 24-V version. This regulation is safe and fulfills all requirements and functions our convectors demand.

Thank you for your understanding.